Gearbox overhaul, photo and video

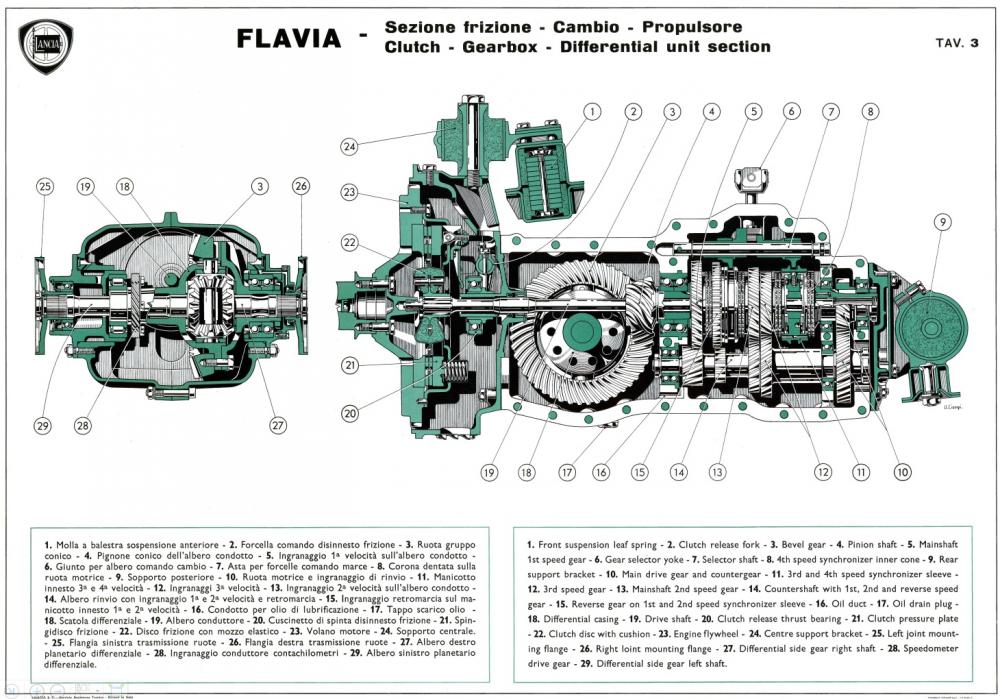

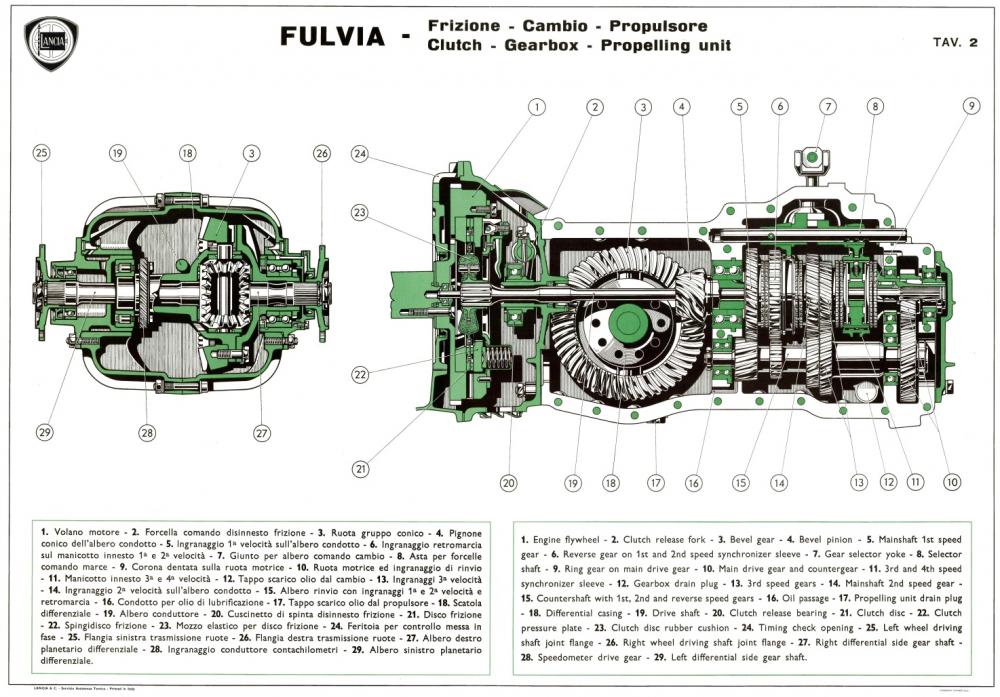

In the drawing above, you see what Huib calls the greatest miracle in automotive history. Number 19 is the input shaft. It slides into the clutch plate. Then it runs straight through the differential and the hollow main shaft. Ultimately, it drives the highest gear which sits at the end of the gearbox. The shaft is no thicker than a cigar and yet transmits 90 hp, and in the case of a 1.6HF competition car, even 161 hp.

The Fulvia and Flavia gearboxes are virtually identical. They are built to last. After about 50 years and several hundred thousand kilometers, they usually need a good service. You could even call it an overhaul.

If a roughneck has driven the car, there can be quite a bit of wear on the synchromesh rings. If the same oil has been used for too long, which 50 years ago wasn't nearly as good as today's synthetic gearbox oils with nanotechnology, it mainly requires a good cleaning. There's black residue everywhere. Soot. The teeth of the crown wheel and pinion are sliding against each other. That's the only point in the gearbox where significant heat is generated, and it's so much that it burns oil. Clean it thoroughly. Replace the seals. The copper bushings. Measure and check everything. Put in synthetic oil. (We use Millers CRX75W90NT). Go for it. When we're done with it, there won't be a car with a gearbox that shifts better than the Fulvia or Flavia.

Testing one of the selector forks.

The selector fork allows you to shift between two gears. In the 4-speed gearbox, it's between 1 and 2 and between 3 and 4. There's a separate lever for reverse. The 5-speed gearbox has three selector forks: between reverse and 1, between 2 and 3, and between 4 and 5.

Checking the ball bearings.

The gearbox contains ball bearings, needle bearings, and plain bearings. The ball bearings are RIV (later acquired by SKF), SKF, or FAG. Three of these bearings have a flange. These are special bearings. They are expensive and difficult to find. These days, it's a bit easier. The question then is whether it's a Chinese knock-off (you definitely don't want one), NOS (New Old Stock, or old production still on the shelf), or new SKF or FAG production. Huib prefers original. So, either leave the bearing in place (if it's in good condition) or replace it with NOS.

Check the play in the bushings of the control yoke

The yoke is connected to the shift stick. The yoke enters the top of the gearbox via bronze bushings. The outer bushing is the part of the gearbox that wears the fastest. If there's any play, the gearbox will throw oil out over de top. In the second series gearboxes, the yoke is thicker. This reduces pressure on the bushings and reduces wear. Furthermore, there's an O-ring in the top bushing, which also helps prevent leaks. Even the second-generation gearbox will eventually need new bushings.

Difficult to shift into second gear.

The conclusion is that the synchromesh is worn. In practice, this is rarely the case. A former Lancia mechanic told Huib on his deathbed what he could do to shift smoothly into second gear. It involves a slightly different method for installing each synchromesh ring. The factory didn't do it because the total assembly time would be an hour longer. Casa Lancia does it unless the customer requests otherwise. All gears, including second, shift incredibly smoothly.

Flavia gearbox.