Engine

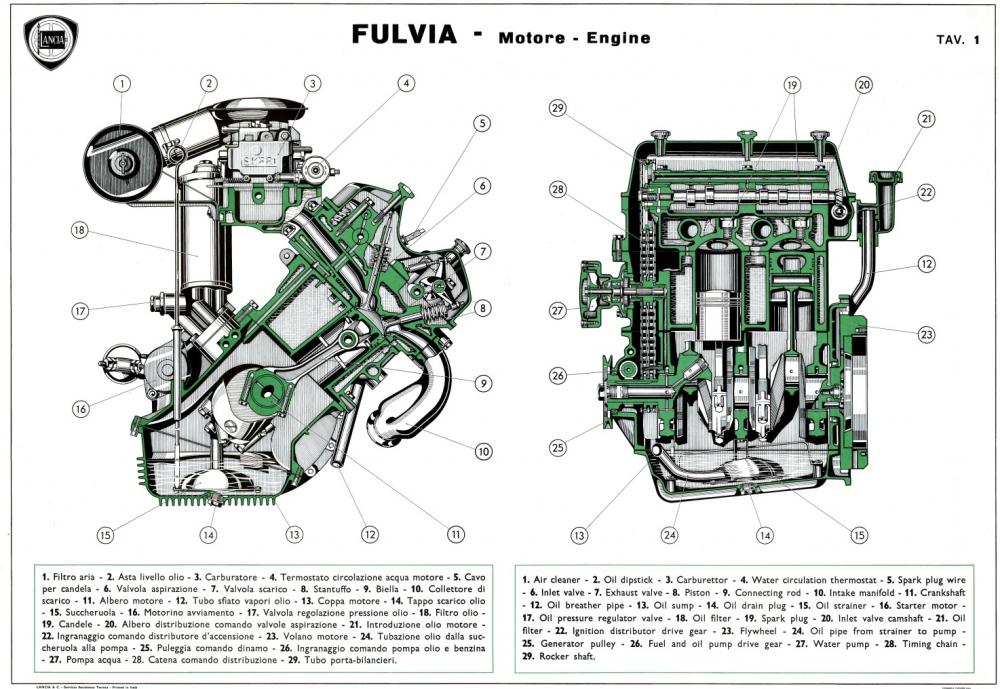

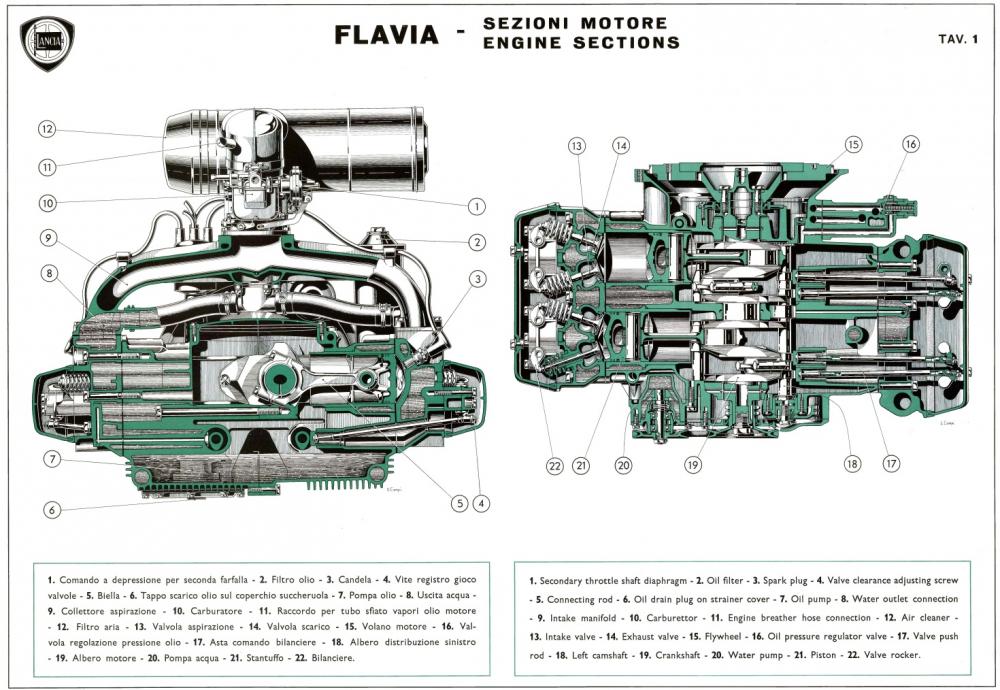

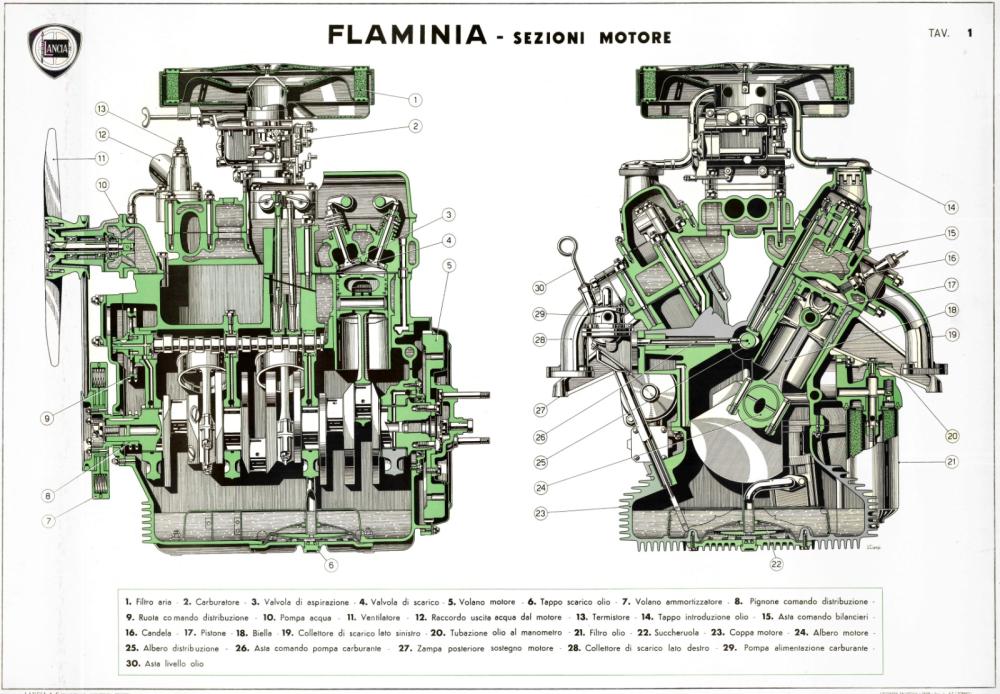

Fulvia Flavia Flaminia

Even if you know about engines, there's something you might not immediately think about, even though it's important. All three are short engines due to their V or boxer construction.

The Flaminia has a V6 engine. The engine is derived from the Aurelia engine, which was the first V6 engine in series production. The crankshaft has only four main bearings instead of seven in a 6 in line engine.

The Flavia is a 4 cylinder boxer engine with three main bearings. The Fulvia engine is a narrow V4 engine with three main bearings. An 4 in line engine has five main bearings. A crankshaft always flexes slightly due to the forces exerted on it. Lancia used the very best crankshaft steel for its crankshafts. However, if your crankshaft has fewer main bearings, it will always flex more. This means you have to be careful with the ignition advance. Due to the narrow-V design and relatively high power output, this is especially true for Fulvia engines. An incorrect adjustment can easily make the difference between an engine lasting 100,000 km or 500,000 km with little or no oil consumption. Casa Lancia will never install an ignition with vacuum advance. When we disassemble a Fulvia engine, we can see from the wear on the bearings whether the ignition was set correctly. Some manufacturers of ignitions offer the option of vacuum advance. 123 ignition is one of them. 123 ignition makes good ignitions. Casa Lancia advices to stay away from vacuum advance.

For the HF engines, Lancia hardened the crankshaft by nitriding. The surface is hardened to 1mm. The crankshaft flexes less. This means less vibration and less losses, which translates to a longer lifespan, lower fuel consumption, and more power. During engine overhauls, Casa Lancia offers the option of hardening the crankshaft to 4 mm thickness with a special process. The crankshaft does often bend during the hardening. The technique involves also re-straightening the crankshaft. The crankshaft, flywheel, pulley, connecting rods, and pistons are balanced with original Lancia bob weights. Through the super hardening and balancing you will have a different engine at very little extra cost.

During engine overhauls, we create a WhatsApp group with the customer for photos. Below are the links to WhatsApp chats. These are not exhaustive. Focused precision work and the thought of taking photos don't go hand in hand. Sometimes someone walks by and makes the photos.

In the chat, you can see how the edge of the pistons at top dead center is perfectly aligned with the top of the cylinder block. This is crucial for perfection. This was the case with the original Mondial pistons. This isn't the case with commercially available imitation pistons. That's why we make the pistons ourselves, precisely according to Lancia's drawings, from an aluminum alloy and with the precision customary for WRC engines.

The Fulvia has a cast iron cylinder block into which the cylinders are bored. Flavia and Flaminia have aluminum engines with steel cylinder liners. During an overhaul, you're required to buy new liners and new pistons. New cylinder liners are expensive. Often, the old liners are still in good condition. They can be bored to an oversize, for which we manufacture oversized pistons. This saves considerably on costs.

Whatsapp chat Flaminia motor The engine isn't finished yet. I'll add progress to this chat. And an exciting video on the test bench.

For Flaminia and Aurelia, it's sometimes necessary to replace connecting rods. We manufacture these ourselves.